PIR (Polyisocyanurate Foam) Chinese name is "polyisocyanurate", also known as "polyisocyanurate", also known as "polyisocyanurate foam PIR" or "triester PIR" ".PIR is a foamed material which is reacted with polyether by isocyanate and reacted with polyether. Its physical and fire resistance is superior to that of general composite insulation material. It is an ideal organic low temperature insulation material with thermal conductivity. Small, lightweight, shockproof, adaptable, can be widely used in high-speed rail, ship, warship, medical purification and other high-demand duct system.

The main features of PIR duct materials:

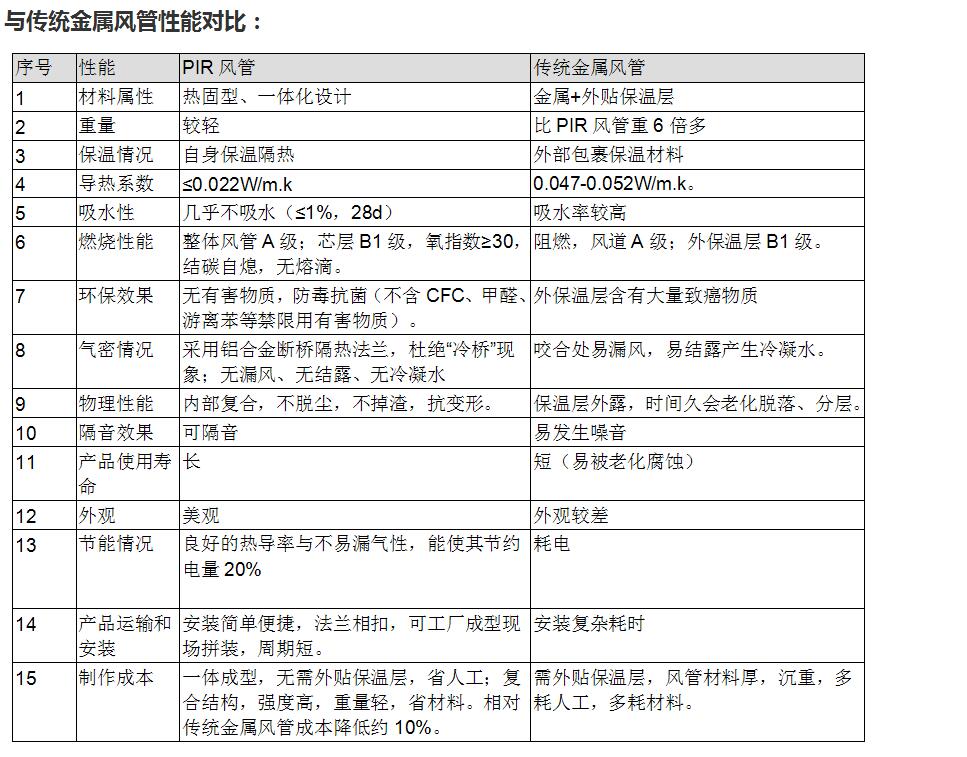

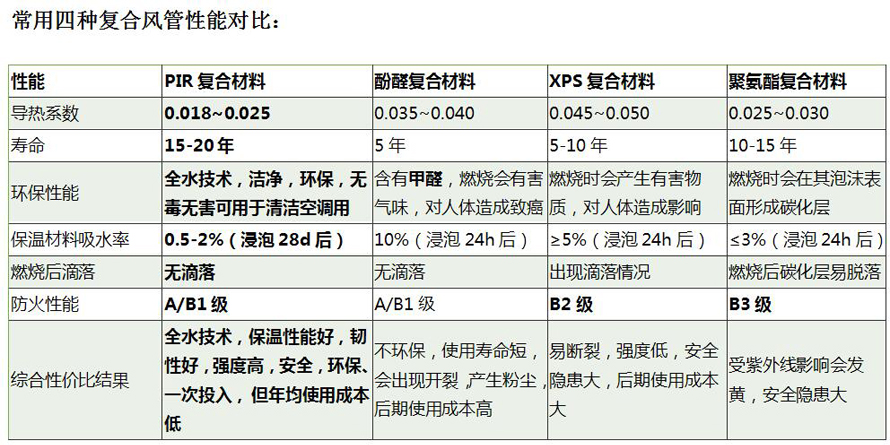

The PIR duct composite developed by Jiawei Technology uses water-foaming technology, a water-foamed modified PIR polymer material composed of high-quality polyol and isocyanate.Its physical and fire resistance is superior to general composite insulation materials. It has passed GB 8624-2012 "Classification of Combustion Performance of Building Materials and Products" B1, EN 45545-2:2013 R1 HL3, TB/T 3237-2010 fire test, An ideal organic low-temperature insulation material with low thermal conductivity (thermal conductivity ≤0.022W/m·k), good air tightness, oxygen index, flame propagation and other aspects have reached the international advanced level.Contains no harmful substances such as CFC, formaldehyde, free benzene, etc., water absorption rate ≤1%, anti-corrosion, anti-fungal, no dust removal, no slag, anti-deformation, no condensation, neutral, no use environment Bad effects and good strength and toughness.Compared with the traditional galvanized iron duct, the cost of construction is reduced by about 10%.Can be widely used in high-speed rail, ships, warships, medical purification and other high-demand duct systems.

The main technical parameters:

(1) Wind tunnel fire performance: non-combustible class A

(2) Core fire performance: flame retardant B1

(3) Thermal conductivity of the core: 0.022 ± 0.001 W / mK (23 ° C)

(4) Formaldehyde free benzene content: 0

(5) Pressure bearing strength: ≤ 2500Pa

(6) Core density: ≥50kg/m3

(7) Core closed cell ratio: 98%

(8) Sheet size: 4000mm × 1200mm × 10-40mm, special length thickness can be customized

(9) Surface layer thickness: 0.05, 0.08, 0.10, 0.18, 0.22, 0.50mm

(10) Surface bonding strength: 0.14MPa

(11) Core compression strength: 343kPa

(12) Water absorption rate of the core: ≤1.0%

FEEDBACK

Please fill in your requirements and receive your information and arrange for someone to contact you immediately.